There is two main type of motor use in 3D printer, servo motor and stepper motor, servo motor is less common because of it higher cost, and servo also consider a close-loop solution, e.g, it know if current location hence better quality.

I'm not going to detail about servo motor, you can get more detail from wiki, as for stepper motor, you just need to know few key property:

Step angle is the single step rotation angle, most type version is 1.8 degree per full step, 200 per revolution.

Micro stepping is the subdivision of the single step, and typical stepper controller support up to 1/16 step, 1/32 is less common, Higher micro step increase the resolution of the printer.

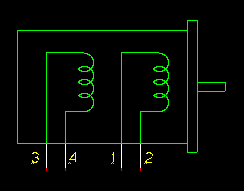

Bipolar or Unipolar is the way the motor is configure. Below is bipolar internal wiring.

And here is the internal wiring for unipolar. Unipolar motor can become Bipolar. typical stepper motor have 4, 6 or 8 wire, 5 wire are less common and require separate controller then the normal version.

Motor size is set by the NEMA standard, the most common size is NEMA17, next is holding torque or holding force of the motor, Z, Y and Z normally require 13.7N-cm/19.4 ozf.in and for gear extruder require 40 N.cm, recently we are seeing increase use gear stepper motor for extruder.

For the most optimize micro stepping, choose motor that have voltage range of 3-5v and current range of 1-1.15A. It this true for stepper controller that have current-limiting feature such as Pololu A4988.

Shaft size typically 0.5mm diameter. Make sure you get the correct pulley with the right bore size.

Motor Controller chip provide the control to set the direction and step, it normally allow user to control of the stepping rotation resolution such as full, half, 4th, 8th, 16th and 32 step. higher the step higher the resolution. Another thing to take note is the output current, higher the current mean you can drive a bigger motor.

There is a trip-pot allow you to set the desire current. If you building printer from parts, make sure you check the motor current is setup correctly, test the perfomance of your motor by check if it too running too hot then it maybe over current, also if when you try to hold the rotation of the motor shaft and it skip step, it maybe under current, both case you need to adjust the power using the trip-pot. Be careful not to short the circuit during adjust, else you may burn the controller.

Also in the firmware configuration.h, there a are that section that the step per unit . You need to adjust this part when you have the correct pulley and stepping.

No comments:

Post a Comment